Furthermore, on a volume basis, the pressurized physically activated carbon, with a high bulk density, showed much higher effective ethanol uptake than chemically activated carbon. Because of the large number of pressurization-induced pores of appropriate size, the pressurized physically activated carbon showed effective ethanol uptake comparable with that of chemically activated carbon on a weight basis. The meaning of ACTIVATED CARBON is a highly adsorbent powdered or granular carbon made usually by carbonization and chemical activation and used chiefly for purifying by adsorption called also activated charcoal. In this study, we investigated the applicability of the pressurized physically activated carbon as an adsorbent in activated carbon–ethanol AHP systems. Recently, we developed a pressurized physical activation method that can produce activated carbon with a well-developed pore structure and characteristic pore size distribution. Moreover, although physical activation can produce inexpensive activated carbon, the limited pore development limits the ethanol uptake. Although chemically activated carbon with highly developed pore structures exhibits good ethanol adsorption, the associated high production costs inhibit its practical application as an AHP adsorbent. Please include the compounds and concentrations of the waste stream and date at which the rental is required.Activated carbon is a suitable adsorbent for adsorption heat pumps (AHPs) with ethanol refrigerants. This blog is also summarised in a 2 min video. But how do they work and do you need one Here’s a simple overview of how active carbon filters work, what they remove and the limitations. If rental units are needed, please contact PCC. Written by Magnus Jern Activated carbon filters are pretty miraculous in terms of their abilities to remove contaminants, odor and bad taste from tap water. This allows manufacturing plants to keep running when the shutdown would have been otherwise required. PCC can assist in the disposal, reactivation, and recycling of the spent carbon.Īdsorbers may be rented for during the maintenance of thermal oxidizers. Reactivation allows for recycling and reuse of the spent carbon. The spent carbon can either be disposed of or reactivated. Once the carbon’s adsorption capacity has been reached, the spent carbon must be removed from the adsorber and re-filled with fresh carbon. During breakthrough, the activated carbon can no longer adsorb organics, and the spent carbon must be removed and replenished with fresh carbon.

#Activated carbon code#

Customized ASME Code designs are available.Īctivated carbon achieves high removal efficiencies for a large number of VOCs until it has reached its usable lifespan and breakthrough occurs. All of these adsorbers have been designed to have a low-pressure drop, excellent flow distribution, and resistance to corrosive compounds. Larger flows have been treated by using adsorbers in parallel. PCC’s Carbon Adsorption Process (PCC-CAP™) Adsorbers are of a modular design and can handle a range of vapor flows from 20 to >20,000 cfm.

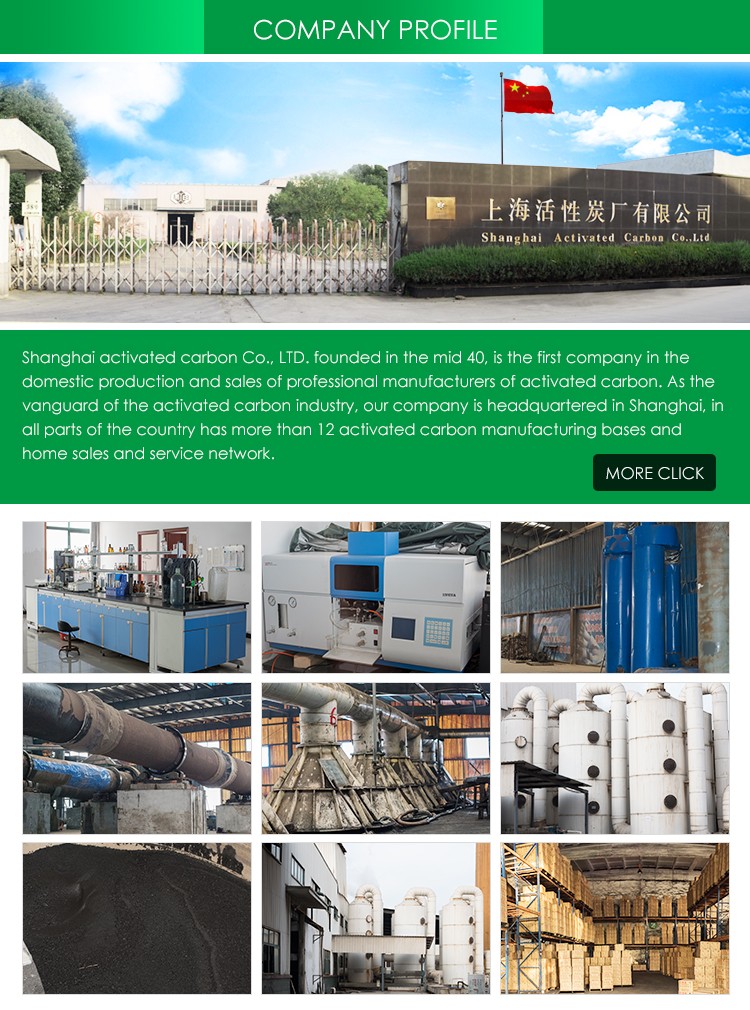

Finally, the treated effluent stream exits the adsorber, achieving environmental compliance and reduced emissions. Within the carbon bed, VOCs, such as benzene or trichloroethylene, are captured and absorbed into the pores of the activated carbon. Within the adsorber, the waste stream is injected into the vessel with an excellent flow distribution and a minimized pressure drop. Activated carbon adsorbers are effective in industrial applications, such as vapor emission control and odor removal. Adsorbers are vessels or modules that contain activated carbon for the purpose of removing contaminants from a process stream. Activated carbon, also called activated charcoal, activated coal, or carbo activatus, is a form of carbon processed to be riddled with small, low-volume pores.

0 kommentar(er)

0 kommentar(er)